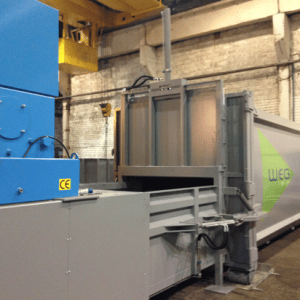

Compactors

Stationary Compactor

INESTA Stationary compactors are robust and designed for commercial & industrial use

INESTA Stationary compactors are robust compactor that was designed to be used at the commercial and industrial sites where high volume of recyclable and non-recyclable material is generated:

- Cardboard;

- Paper;

- Burnable waste material utilised in the incineration plats;

- Plastic;

- Mixed waste;

- Textile etc.

The name of the INESTA Stationary compactor identifies compactor’s operation technique, where the main two components of the compactor are:

- Durable, freestanding and high compacting force pressing unit, that consists of a smoothly running press piston, which is operating horizontally. The obtained pressing force allows to compact waste material considerably. An average compacting ratio of the INESTA Stationary compactor is 3:1 for medium density waste material, for example mixed waste. Nevertheless, it should be noted that compacting ratio will increase up to 10:1 when certain type of waste material is compacted, for instance shredded paper employed for packaging.

- Waste material fed into the INESTA Stationary compactor is compressed into a detachable container that is removed when full, to the landfill or other waste collection sites to be emptied. This solution allow several containers to be used, in order to ensure that a full container can be replaced with an empty container to achieve continues waste feeding system into a compactor. INESTA can design and produce different capacity containers that can be manufactured according to various standards. Moreover, all common lifting equipment can be installed on the container to suit the lifting devices that are available to the customer.

INESTA Stationary compactor are ideal for deployment in the following locations:

- Shops, shopping malls, markets;

- Hospitals, hotels, retirement homes;

- Industrial, temporary waste management and storage plants;

- Restaurants, banks, sport and leisure centers;

- Warehouses, transport and customs terminals;

- Bus and train stations, ports, airports.

Our highly experienced and skilled staff tailor every order individually, to offer customers the most cost effective, high quality, safe and environmentally-friendly compactor solution available.

Accessories that are available to INESTA Stationary compactor are:

- Various hopper types tailored according to the customer requirements;

- Different wheel types installed on the container, for example, back door corner wheels;

- Bottom frame of the container manufactured according to a specific standard;

- Odor removing system, such as ozone generator or activated carbon filter;

- Fire hose connector;

- Compactor’s fullness level indicator via Sick sensor;

- Auto start sensors;

- GSM module;

- Hydraulic back door opening system of the container;

- Manual or hydraulic locking system for the container and pressing unit;

- Tipping device can be integrated into a compactor or can be installed as a separate device;

- Custom made compactor design;

- Longer guiding rails;

- More options are available, please contact your local us via email or phone: hannu@inesta.net / inese@inesta.net / +371 22323532 / +37129404069.

Key features:

- Compression of waste horizontally

- The pressing force strength of our stationary compactor is achieved thought two hydraulic cylinders that are positioned in a cross pattern with a powerful hydraulic unit;

- This solution allow several containers to be used;

- We offer mechanical (where two turnbuckles are used from both sides) and hydraulic locking mechanisms using specially tailored software which ensures automatic locking of the pressing unit to the container;

- CE compliant.

| Technical Specification | |

|---|---|

| Compacting force | 280 kN (28 tones) 380 kN (38 tones) 400 kN (40 tones) |

| Steel grade | S355 |

| Hydraulic cylinders | 2 pieces in 280st and 380st 1 straight in 400s |

| Electrical motor | 5.5 kW or 7.5 kW or 11.0 kW or 15 kW |